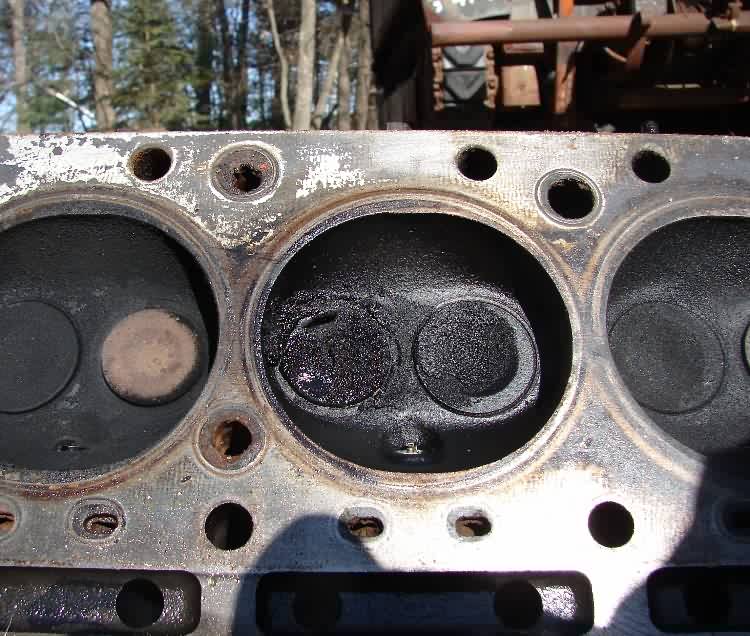

I finally got the head off in this nicer weather and found a burned valve.

I also found what looks like woodstove cement on the valve surface under the pictured carbon residue. This actually explains a lot.

When I bought my CCKW I purchased it sight unseen (BIG MISTAKE!). The agreement was that I would hold back some of the total until I was satisfied with the condition.

When it arrived it would not run as the fuel was crappy and the tank was loaded with crud.

To check the engine condition I was able to check compression, spark, dwell, etc and did so. Compression in all cylinders was between 125 and 130 psi.

I got the engine running and was able to run it and extended idle it. I could not drive the truck or stress test the motor as there were no brakes and it could be driven on the road.

While going to put it on the road last fall a miss developed. An infrared thermometer indicated substandard temperature from the #3 cylinder. A compression check revealed 0 compression and a leak down test sent air directly to the exhaust system.

Strange that it would be fine for so many years and then have valve problems so quickly...but it happens.

Upon disassembly I also found that the manifold gasket was for a 302 and not a 270. I also now have a valve here whose surface is covered in woodstove cement. Did the previous owner "patch" the valve to quick close the burn so he could quickly sell the truck with a bad motor to an unsuspecting buyer. One will never know.

Where can valves be purchased.

Bill